A Vibrating Motor Drive unit works on the principle of rotating masses, and as such is particularly suited to high capacity feed applications where delivery flow is fixed or requires infrequent adjustment.

Robustly constructed, vibrator motor drive units are ideal for high capacity feeding and conveying heavy and bulk loads – with a high output force in relation to the weight of material.

Also suited for screening, compacting and elevation applications, Applied Vibration motor drives are known for their reliability – being easy to use and connect, and requiring practically no servicing.

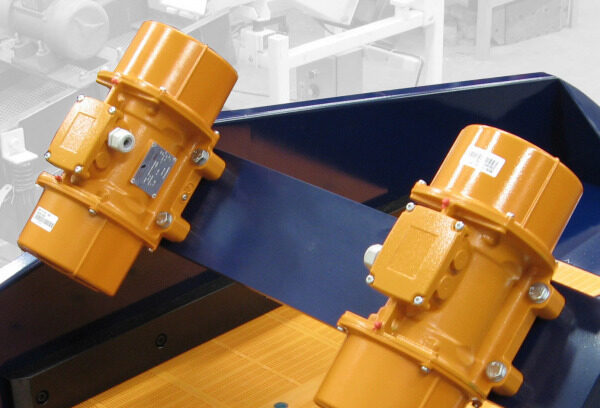

Twin Motor Drive

Vibrating motor drives are often used in pairs as ‘Twin Motor Drives’, and when used as such can provide higher volume feeding and product conveying with throughput rates up to 500 M3/hr.

Twin motor drives can be combined with an inverter based control, meaning that although Electromagnetic Drive Units are better suited to mid-flow adjustment, vibrating motor drives do allow for a reasonable degree of flow rate adjustability.

Motor drives and twin motor drives are often the first choice for larger conveying equipment, as the high amplitudes are ideal for conveying heavy and bulk loads.

Motor Drive Demonstrations

| Features |

|---|

| Output force high in relation to weight |

| Used for high capacity feeding and conveying heavy bulk loads |

| Twin Motor Drives – provide throughput rates up to 500 M3/hr |

| High amplitudes |

| Robust construction |

| Benefits |

|---|

| Easy set up and use |

| Practically no servicing required |

| Robust construction well suited to heavy industries |

| High volume feeding for efficient handling |